| Features |

Lineup includes the general purpose MCT-1150 and the rigid and durable MCT-2150 with high precision ball screw and thicker crosshead Lineup includes the general purpose MCT-1150 and the rigid and durable MCT-2150 with high precision ball screw and thicker crosshead

Space-saving design for use on a table. 250(W)×405(D)×711(H)mm Space-saving design for use on a table. 250(W)×405(D)×711(H)mm

Precision load cell ready for immediate use. Automatic calibration on start up lets you jump straight into testing. No need to manually Precision load cell ready for immediate use. Automatic calibration on start up lets you jump straight into testing. No need to manually

calibrate the load cell.

Use your favorite jigs. Your favorite force gage and push-pull gage jigs can be used (with M6 screws). *M6 male screw Use your favorite jigs. Your favorite force gage and push-pull gage jigs can be used (with M6 screws). *M6 male screw

Print essential information. Maximum load and displacement can be printed with the AD-8126 mini printer (sold separately). Print essential information. Maximum load and displacement can be printed with the AD-8126 mini printer (sold separately).

Ideal for use in the field. Easily configure testing speed digitally. Displacement display is standard. Ideal for use in the field. Easily configure testing speed digitally. Displacement display is standard.

|

|

|

| Data capture software included |

| Supported OS: Windows XP, Vista Business, 7Pro (32bit version), USB: Ver 2.0 or higher |

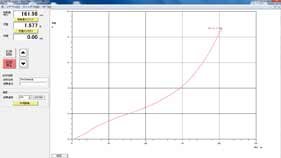

MCT-Logger [Recording software]

(Included with MCT-1150)

Real-time graphing. Calculate and display maximum value

and displacement. Or enter curve data in CSV format. |

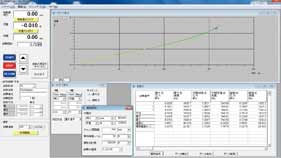

MSAT-Lite [Data processing software]

(Included with MCT-2150)

Displays operation and processing results. Performs data

analysis and graphing. Or enter curve data in CSV format. |

|

|

|

| Use for a variety of material testing (Caution: The MCT series is not waterproof) |

|

| Measuring strength required to press a button |

Packaging heat seal strength test |

- Measure the strength required to - Measure the strength required to

press a button

- Measure push sensation |

- Obtain the ideal sticking strength; - Obtain the ideal sticking strength;

not so strongthat a package cannot

be opened and not so weak that a

package will open by itself. |

< Product configuration >

MCT-1150 or MCT-2150

Pressure Plate φ15mm JM-X004-500N

Vice JM-X011-500N

Introduction video (Duration: 9 sec.) Introduction video (Duration: 9 sec.) |

< Product configuration >

MCT-1150 or MCT-2150

Parallel screw action jaw JM-JFM-500N×2

Introduction video (Duration: 12 sec.) Introduction video (Duration: 12 sec.) |

|

|

| Plastic bottle buckling strength test |

Food packaging film puncture test |

- Buckling strength test for plastic - Buckling strength test for plastic

bottles

- Measure the force needed to crush

plastic bottles |

- Measure the force needed to - Measure the force needed to

pierce packaging film.

JIS Z1707 Standard

Needle φ1mm Edge R 0.5mm |

< Product configuration >

MCT-1150 or MCT-2150

Pressure Plate φ60mm J-C3-1KN-U

Introduction video (Duration: 17 sec.) Introduction video (Duration: 17 sec.) |

< Product configuration >

MCT-1150 or MCT-2150

Puncture Testing Jig JM-CL-100N

Introduction video (Duration: 17 sec.) Introduction video (Duration: 17 sec.) |

|

|

| Testing push strength for removing medicine from PTP packaging |

Syringe resistance test |

- Test push strength required for PTP - Test push strength required for PTP

packaging for medicine.

- Measure strength required to push

medicine out of blister packs (PTP).

Strong packaging makes removing

medicine difficult. Conversely, weak

packaging poses the opposite problem.

Measuring the optimal strength required

to push out medicine is essential. |

- Measure the strength required - Measure the strength required

to push down a syringe.

- Check the smoothness of the

plunger movement |

< Product configuration >

MCT-1150 or MCT-2150

Pressure plate φ5mm JM-X008-500N

Or additionally φ15mm JM-X004-500N

Puncture Testing Jig JM-CL-100N

Introduction video (Duration: 17 sec.) Introduction video (Duration: 17 sec.) |

< Product configuration >

MCT-1150 or MCT-2150

Pressure Plate φ15mm LM-X004-500N

Vice JM-X011-500N

Introduction video (Duration: 53 sec.) Introduction video (Duration: 53 sec.) |

|

|

| Flexible cable pull out test |

Tablet strength test |

- Measure the connecting strength - Measure the connecting strength

of a flexible cable

- Weak cables are pulled out too

easily |

- Tablet strength test - Tablet strength test

- Test the compression (crushing strength) needed to break a tablet. |

< Product configuration >

MCT-1150 or MCT-2150

Parallel screw action jaw JM-JFM-500N

Vice JM-X011-500N

|

< Product configuration >

MCT-1150 or MCT-2150

Pressure plate for STA/STB φ60mm J-C3-1KN-U

Pressure plate φ5mm LM-X008-500N

Or additionally φ15mm JM-X004-500N

Introduction video (Duration: 12 sec.) Introduction video (Duration: 12 sec.) |

|

|

| Food container metal fastener strength test |

Bending strength test |

- Measure the strength of metal - Measure the strength of metal

fasteners for containers

- Ensure fasteners do not detach

when lid is opened. |

- Measure bending strength - Measure bending strength

- Measure the bending strength

of plastic, metal and ball point

writing utensils |

< Product configuration >

MCT-1150 or MCT-2150

Parallel screw action jaw JM-JFM-500N X2

|

< Product configuration >

MCT-1150 or MCT-2150

Bend testing jig: edge R2mm JM-B-500N

Or additionally edge R5mm JM-B1-500N

Introduction video (Duration: 18 sec.) Introduction video (Duration: 18 sec.) |

|

|

| Container film opening force test |

Safety cover |

- Measure the force needed - Measure the force needed

to open (peel) a film lid on a

container

- Peeled at an approximately

45 degree angle

- Compatible with containers

of up to 120mm diameter and

up to 120mm height. |

- Prevents samples from being - Prevents samples from being

broken and scattered during

measurement

- Prevents samples from being

broken and scattered during

measurement |

< Product configuration >

MCT-1150 or MCT-2150

Container peel testing jig

Introduction video 1 (Duration: 17 sec.) Introduction video 1 (Duration: 17 sec.)

Introduction video 2 (Duration: 26 sec.) Introduction video 2 (Duration: 26 sec.)

Introduction video 3 (Duration: 17 sec.) Introduction video 3 (Duration: 17 sec.)

|

< Product configuration >

MCT-1150 or MCT-2150

Parallel screw action jaw JM-JFM-500N X2

|

|

|

|

| Specifications |

| Model |

MCT-1150

(General purpose model) |

MCT-2150

(High performance model) |

| Table / floor model |

Table model |

| Maximum capacity |

500N |

| Crosshead stroke |

400mm |

370mm |

| Effective stroke*1 |

315mm |

285mm |

| Crosshead speed |

10-300mm/min: Within 5% of the set value*2 |

| Crosshead speed setting |

Digital setting: 1mm/min increments within the above range |

| Crosshead speed and load capacity |

Full speed range at maximum capacity |

| Crosshead return speed |

Three speed settings: 10, 100, 300mm/min |

| Load measurement accuracy |

±0.2% F.S |

500N to 50N: ±0.2% F.S

50N to 5N: Within 2% of indicator value

5N and lower: Within 0.1N |

| Load display resolution |

0.1N |

0.01N (0.1N will display for values over 100N) |

| Load calibration |

Auto-zero function (calibration unnecessary) |

| Displacement display |

000.0mm (Min. 0.1mm) |

00.00mm (Min 0.01mm: 0.1mm

will display for values over 100mm) |

| Included software |

MSAT-Lite, MCT-Logger |

| Safety mechanisms |

1. Upper and lower displacement stroke limits

2. Overload limit (automatic shutdown when load cell passes 105% of rated capacity)

3. Emergency stop switch |

| Dimensions (W × D × H) |

250 × 405 × 711mm |

| Weight |

17kg |

18kg |

| Power supply |

AC90 to 240V 1Ø 50/60Hz |

| Power consumption |

90W |

| Operating ambient condition |

Temperature: 5 to 40°C Humidity: 20 to 80%RH |

| Recommended ambient conditions |

Temperature: 23 ±2°C Humidity: 50 ±10%RH |

| Standard equipment |

Instruction manual, 500N capacity load cell, computer software (CD-ROM), USB cable |

|

*1 When using standard screw action jaws

*2 Unladen

|